source GAIA package: Sx_MilitaryTimes_M6201310306170005_5675.zip Origin key: Sx_MilitaryTimes_M6201310306170005 imported at Fri Jan 8 18:18:10 2016

The Marine Corps will begin fielding quick-drying Rugged All Terrain boots in the next year. It is the beginning of a Corps-wide transition to the next-generation RAT boot as the only footwear authorized for wear with utility uniforms, whether deployed or in garrison.

The Marine Corps will begin fielding quick-drying Rugged All Terrain boots in the next year. It is the beginning of a Corps-wide transition to the next-generation RAT boot as the only footwear authorized for wear with utility uniforms, whether deployed or in garrison.

The anticipated contract for 150,000 hot-weather and 150,000 temperate-weather boots will enable the Corps to issue the footwear to recruits as part of their seabag in fiscal 2014, which begins Oct.1. It will also become available for purchase by those already in the fleet.

Marines will be required to own a pair within two years of the date they are added to the seabag, said Barb Hamby, a Marine Corps Systems Command spokeswoman at Marine Corps Base Quantico, Va.

The RAT boot, which has been issued to deploying Marines since 2009, will replace the Marine Corps Combat Boot, an update to the Infantry Combat Boot fielded in 2002. During the transition period, both RAT boots and MCCBs will be authorized for wear.

The effort to develop faster-drying boots is the latest in a slew of initiatives — such as quick-dry tropical combat uniforms and efforts to create lighter, streamlined gear — intended to prevent fatigue, discomfort and common but potentially debilitating fungi that can take a Marine off his feet.

Three key changes

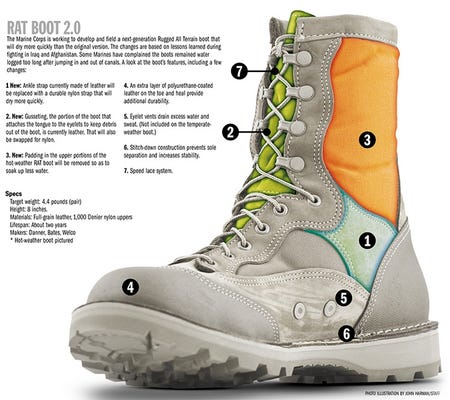

Military boot manufacturers will be asked to replace the leather ankle straps and gusseting in the hot- and temperate-weather RAT boots with heavy-duty nylon to speed dry times, according to a pre-solicitation to industry updated on FedBizOpps.gov in late May. The ankle strap, which extends from the heel up and across the ankle, provides stability. The gusseting connects the tongue to the eyelets and is meant to keep out debris.

Additionally, the new design calls for removal of the padding found in the upper side panels of the hot-weather version of the boot, also to promote faster drying.

The changes should be welcomed by Marines, some of whom complain that RAT boots remain wet long after exposure to water. In fact, some Marines chose not to wear the boots issued for their deployment.

"In Afghanistan, they seemed to hold a lot of water when Marines crossed the canals, and the boots were quickly replaced by those who did try them," said Sgt. Jeffrey Carlson, a rifleman with 3rd Battalion, 1st Marines, out of Camp Pendleton, Calif.

Other Marines echoed his sentiments.

"I spent some time wading through the 'beautiful' rivers and streams in that lovely country, and the old boots took a while to dry out," said Sgt. James Cook, a low-altitude air defense gunner with 3rd Low Altitude Air Defense Battalion, out of Camp Pendleton, Calif.

Despite the changes, the new RAT boot will look fairly similar to the current generation; the ankle strap modifications will be the most obvious visual difference.

Troubled history

RAT boots have had an up-and-down history since the Corps rushed them into service in 2006. Marines operating in Afghanistan's mountainous eastern provinces found that their standard combat boots were falling apart after a few months of service in the rough terrain. The solution was RAT boots produced by Danner. Based on one of the company's back-country hunting boots, they performed well in the harsh conditions. A requirement to buy RAT boots for deploying Marines was approved in 2009.

Intent on making RAT boots a standard part of the service's clothing inventory, the Marine Corps decided in 2011 to open competition on the contract for future supplies. While Danner continued to make boots for the Corps, the service also awarded a contract for the hot-weather version of the RAT boot to Bates Footware.

Service officials planned to add the RAT boot to the seabag in 2012, phasing out the Marine Corps Combat Boot, but then procurement efforts hit a snag. Thousands of the Bates boots were recalled because drainage eyelets were falling off and stitches and soles were separating from the boot.

The contract with Bates called for delivery of 105,000 pairs of boots. About 67,000 were delivered before the defects were discovered and production was halted, eventually leading to the recall of 8,000 pairs then fielded — many to Marines deploying to Afghanistan.

Part of what made Danner's version of the RAT boot so stable and durable was its "stitch-down construction," meaning the uppers were stitched to the soles, not just glued. While the production technique makes for a highly durable boot that can be resoled, it is also difficult to master. Bates, which had not produced stitch-down boots before, struggled to maintain quality control as it entered full-rate production.

The Corps awarded a $2.4 million stopgap contract to Danner for 18,000 pairs of RAT boots to alleviate the shortage for deploying Marines. Meanwhile, the service began working hand in hand with Bates to remedy problems. Bates has since resolved the issues and delivered more boots to the service.

Danner will compete for a contract to manufacture the new design, according to Will Pennartz, a company spokesman. Bates representatives could not be reached for comment.

The next-generation RAT boot design now sought by the Marine Corps was not prompted by wear problems with the current design, Hamby said. "The service life of the RAT boot is 24 months," she said. "The current version of the RAT boot meets the service life requirement."

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/DEAUNCJNHNGENHPVJ6LTRZ27JY.jpg)

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/FGETHDCP7FGIVBP6345WI7CYLQ.jpg)

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/ICE6ILJ27VAJBLU5SZZZCKVGLE.jpg)

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/XHCUSJLAJVBIJBGQRFK3AFPZCI.png)

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/KV7P2WGEKRCW7MIDAP63R5GPDI.jpg)

:quality(70)/cloudfront-us-east-1.images.arcpublishing.com/archetype/CURBG5BVO5E7TA7LFDULIP5TGQ.jpg)